@lewm,

The KL Audio is 40kHz, with four 50W horizontally positioned transducers, two each side (200W total) with a UT tank volume of only about 0.78L - that is it's a very powerful machine. Note that the reservoir is 2.4L, but someone recently measured the change in reservoir volume to fill the unit - ergo the UT tank volume. With the very small volume and amount of power available, it does not need any enhancement with chemistry.

Here is a quick summary of UT concepts and some basic thumb rules:

Ultrasonic tanks 'grow' bubbles Principle-of-ultrasound-cavitation-16-The-initiated-bubbles-grow-due-to-evaporation.png (850×553) (researchgate.net) until the bubble collapses. Watch this video between 6:19 and 8:30 Cavitation - Easily explained! - Bing video to see how the bubble collapses.

Here are the basic thumb rules for ultrasonic tanks:

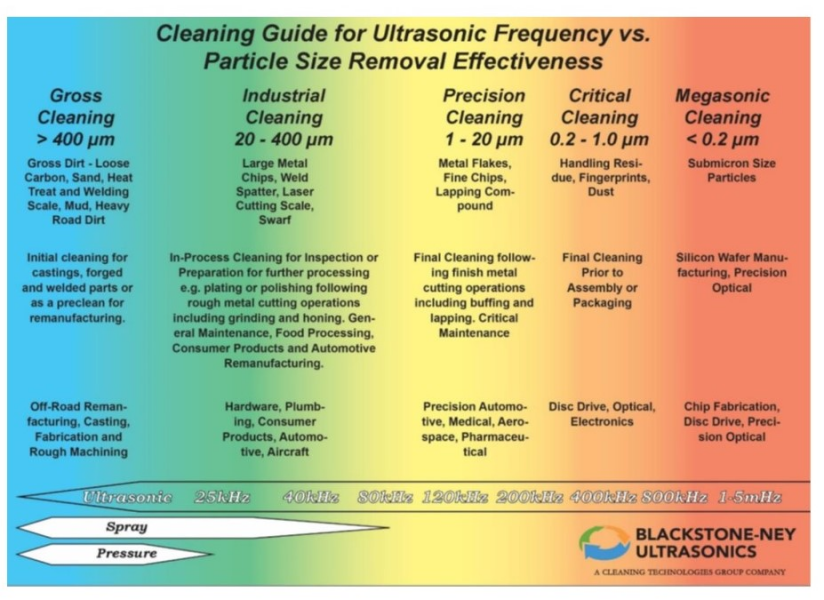

-The power to produce cavitation is proportional to the kHz, so a 120kHz UT needs more power than a 40kHz.

-For ultrasonic tanks, the bubble diameter is inversely proportional to the kHz, so a 40 kHz UT produces a large bubble than a 120kHz UT.

-The cavitation intensity is proportional to the bubble diameter and the tank power (watts/L) but there is a maximum power above which no addition cavitation intensity is obtained.

-The number of cavitation bubbles produced is proportional to kHz, so a 120kHz produces more bubbles than a 40kHz, but smaller bubbles.

-The smaller the tank volume, the more power that is required. It has to do with the ratio of the tank volume to its interior surface area.

-For lower kHz units (<60kHz), if the tank bath flow rate (from filtering or spinning) >50% of the tank volume per minute, cavitation intensity decreases.

For records, in general, the most difficult items to clean/remove are particulate. The paper Adhesion and Removal of Fine Particles on Surfaces, Aerosol Science and Technology, M. B. Ranade, 1987 (Adhesion and Removal of Fine Particles on Surfaces: Aerosol Science and Technology: Vol 7, No 2 (tandfonline.com) shows for aluminum oxide particles, the force (acceleration) required to remove a 10-micron particle is 4.5 x 10^4 g’s, a 1-micron particle is 4.5 x 10^6 g’s and a 0.1-micron particle is 4.5 x 10^8 g’s. A simple brush or wipe is not going to get the smallest particles/debris that can ‘hide’ in the valleys between the groove side wall ridges. As fluid flows past a surface, a boundary layer is developed and depending on its thickness (upwards of 5 microns) it will essentially shield any particles within it. So, agitation is critical in reducing the boundary layer to expose the surface with its particles to the cleaning fluid and the fluid velocity (shear force) that can remove them.

-The boundary layer thickness is dependent on the ultrasonic frequency (high kHz = thinner boundary layer), acoustic energy, and fluid properties (viscosity & density). To get the most effective cleaning, the complete cleaning process has to penetrate the boundary layer to remove the soil and particles that are contained within it. At 40-kHz, the boundary layer 'can' be as thick as 5 microns, while at 120-kHz, the boundary layer 'can' be as thin as 2 microns.

-Lowering the surface tension of the fluid reduces the energy needed for cavitation and can improve cleaning efficiency - better opportunity to penetrate the boundary layer. The KL Audio unit does it by brute power.

-But there is a delicate balance with using chemistry and UT that can improve the cleaning efficiency more than the small expense to the cavitation intensity (more an issue with low power units). But use too much chemistry or the wrong chemistry and it's all downhill.

There is an entire science about particle adhesion and removal and if you wish to entertain yourself here is a good book to start with - Particle Adhesion and Removal | Wiley Online Books.

Beyond all this, if you are going to get into an academic discussion on record cleaning, there is the existential question of just how clean a record needs to be to provide maximum playback fidelity? From my research, the answer is quite complex and a topic unto itself. But absent the details, people default to trial and error, and what they hear. Which is perfectly acceptable, and which is why when someone asks me what is best, I will always say, what is best for you.

Now back to the regular scheduled programming.