Todd a very cool project! Any pics of them all setup? Also is the material rubber or some sort of plastic?

Give Me a 3D Printer and Who Knows What I'll Come Up With...

Last Sat I bought a Bambu Labs X1C for the Black Friday sale ($250 off) and got it set up. On Sunday I got the software up and running and started printing.

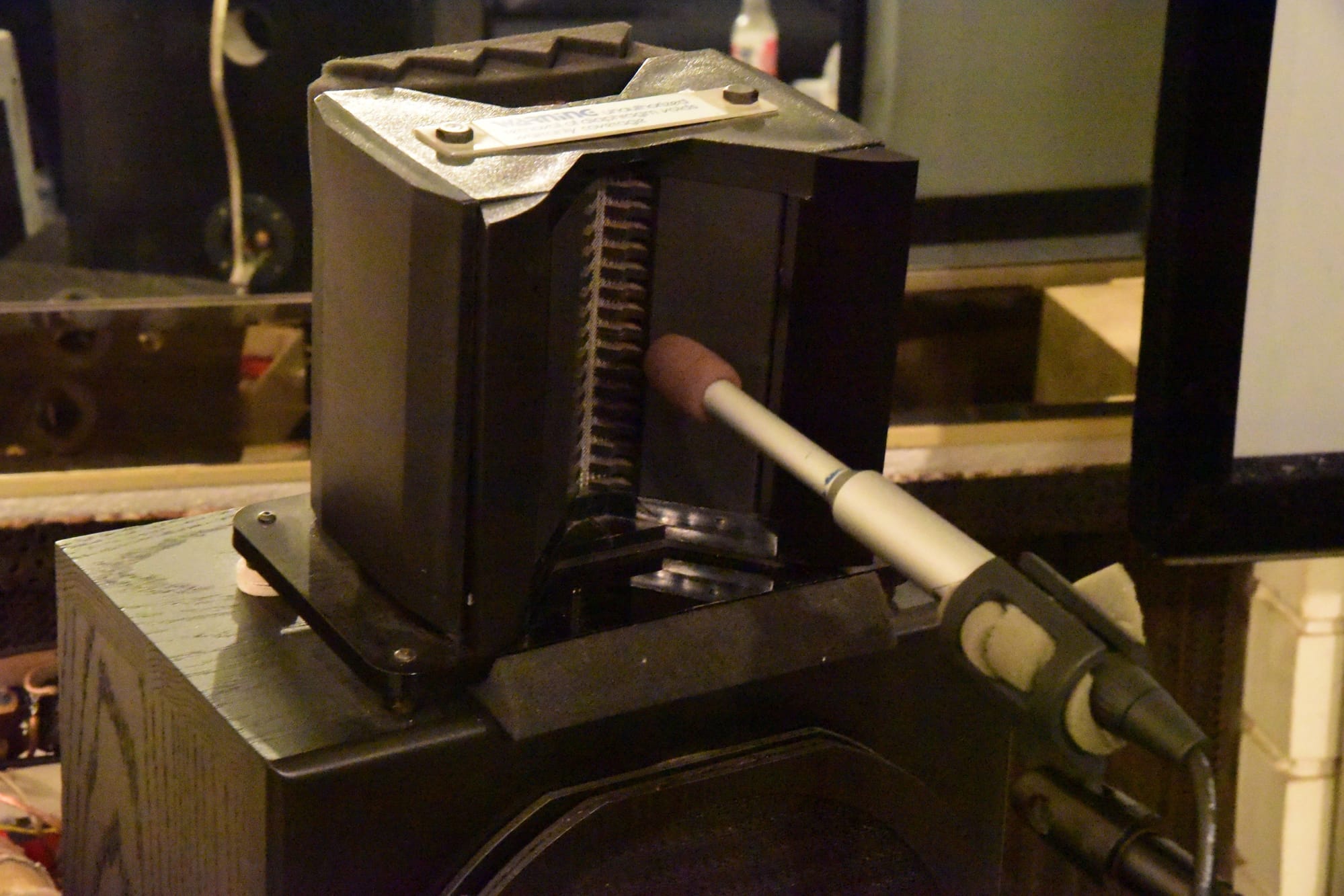

My first job is "wave guides" for the Great Heil. These go at the top and bottom to remove the step and limit/smooth vertical dispersion.

I am using the same technology used for golf balls to reduce the air friction over the material.

This shows the pieces that actually go along the top and bottom and are the width of the top "step" of the Heil so that there is a smooth transition out of the Heil with no steps. There is then an upper and lower piece that will attach to these where the upper piece will have a pair of "wings" that let it rest along the top of the Heil without falling into the gap, and the lower piece will omit the wings but compensate for the rubber gasket.

The curvature follows the curvature of the flairs that I previously designed, had a friend make, and added. Here you can also see the steps that will be "removed" for a smooth path out of the driver.

- ...

- 3 posts total

- 3 posts total